Modelling and verification of sesame seed particles using the discrete element method

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

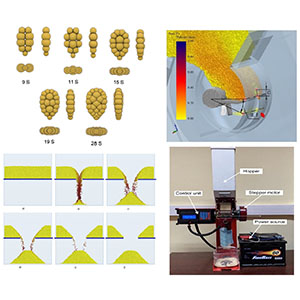

The size of sesame seed particles has been measured and analysed to build a sesame seed particle model using the discrete element method (DEM). Despite the strength of simulations using the DEM method, one of the challenges that still require to be overcome is approximating the form of the actual particles, especially for irregular shapes, to obtain more realistic simulations. Thus, the sesame seed particle was simplified to be quite close to the actual seed forms by drawing an irregular 3D sesame particle model using Fusion 360 software with the average dimensions of five hundred randomly selected sesame seeds. Consequently, a modelling approach for sesame seed particles based on a multi-sphere (MS) method was suggested. In this paper, the simulated results of the sesame particle model were close to those obtained experimentally, with 28 filling spheres. The results for both piling tests and oscillating seed meter calibration have shown that the 28- sphere model is appropriate for modelling the sesame seed particle. Thus, the validity and feasibility of the modelling approach for sesame seed particles we proposed have been verified. Finally, the simulation analysis provided a good prediction for the outflow process of sesame seeds from the oscillating seed meter. The optimum values for the main parameters of the oscillating seed metering device for sowing sesame seeds are 9 mm for seed exit hole clearance, 20° for oscillation angle, and 0.022 sec for opening time, providing a sesame seed rate of 2.7 kg/ha. As a result, it provides a reference for the design and optimisation of oscillating seed meter for sowing sesame seeds.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.