Design of a five-bar duckbill-type mechanism for sorghum transplanting

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

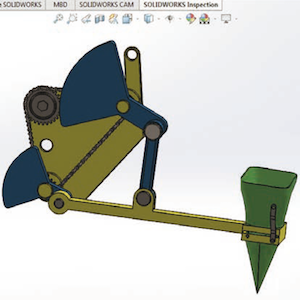

Sorghum seedling transplanting is an essential agricultural activity in Sub-Saharan Africa. However, conventional manual transplanting of sorghum is a time-consuming, labour-intensive, costly activity with a low transplanting rate, uneven plant distribution, and low degree of accuracy. In order to realize rapid and precise sorghum seedlings transplanting, a duckbill-type mechanism has been designed. This mechanism is a five-bar linkage consisting of two crankshafts, two connecting rods, and a duckbillshaped planter to improve the quality of transplanting operations. The study includes kinematic and synthesis analysis through MATLAB software, parts design, and motion analysis using SolidWorks software. After synthesis analysis using a genetic algorithm, the optimal length between the two cranks is 300 mm, the length of the upper crankshaft is 106 mm, the length of the connecting rod I is 169 mm, the length of the connecting rod II is 222 mm, and the length of the lower crankshaft is 67 mm. Furthermore, the speed and acceleration analysis show that the seedlings are planted with zero-speed operation to obtain a high perpendicularity qualification. The results show that the proposed planting mechanism meets the agronomic requirements of transplanted sorghum with a good transplanting rate.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.