A low-energy storage container for food and agriculture products

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

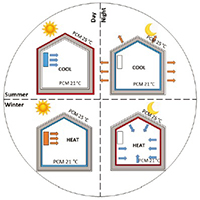

In 2018, the food, beverages, and tobacco sectors within the EU-27 consumed approximately 27,500 ktoe of energy. The food facilities and the food production plants are responsible for a large part of this energy consumption. Current global strategies focus on energy conservation and natural environmental protection, ascribing a lot of importance to building-related analyses. Areas for food storage are essential within the food production chain, as the indoor thermal parameters determine the characteristics of the final products. In this paper, a low-energy storage container is proposed. The envelope of the container is made from sandwich panels with a polyurethane layer paired with two phase change material (PCM) layers. The container is designed to store perishable materials, such as extra virgin olive oil. A storage container prototype, equipped with a mini-split heating, ventilation, and air conditioning electric system, was built to analyse and assess the energy spent during its use. Moreover, the achievable yearly energy savings with respect to a container without the PCM layers was calculated. The results showed that the PCM layers improve the energy performance of the container at an indoor temperature of 20°C with an energy saving of about 27%, and at an indoor temperature of 17°C with an energy saving of over 22%.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.