Development of treated cardboard waste injection machine into the sandy soils

Appendix: 106

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

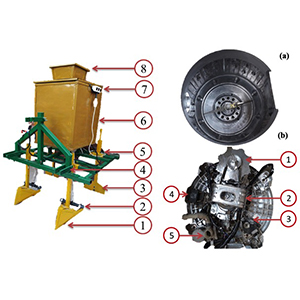

This study aimed to evaluate a new prototype for an injection machine that works in sandy soils using treated cardboard waste. The tests were divided into three major categories: i) the first one was a performance evaluation of the new injection prototype; ii) secondly, study the effect of adding the treated cardboard to the sandy subsoil on reducing the irrigation levels and increasing the moisture content in the root zone of cultivated plants; and investigate sandy soil water storage efficiency and its impact on improving the soil’s properties; thirdly, measurements on water-sensitive crop yields, like potatoes. The new prototype technique was designed using an integrated automatic control system to precisely control the injection discharge rate. So, the injection operation is proportionally synchronised with the tractor’s forward speed. The field experiments were carried out at 0.24, 0.40, 0.57, and 0.74 m sec–1 of tractor forward speeds with 250, 350, and 450 mm of furrow openers’ subsoil depths at 140 and 200 mm of injection widths and 5 and 10% concentrations of cardboard solution. The main results indicated that the maximal consumed energy was 196.08 kWh ha–1 with a field efficiency of 89.05% and an optimal field capacity of 0.281 ha h–1 using the highest variable levels. In addition, the water-saving percentage was 35.80%, while the water storage efficiency was 85.85%. Furthermore, the total economic costs were reduced by 13.88% compared to the traditional silt injection method for the tested control plots.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

PAGEPress has chosen to apply the Creative Commons Attribution NonCommercial 4.0 International License (CC BY-NC 4.0) to all manuscripts to be published.

https://doi.org/10.4081/jae.2022.1354

https://doi.org/10.4081/jae.2022.1354