Effect of the initial moisture content of the paddy drying operation for the small community

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Authors

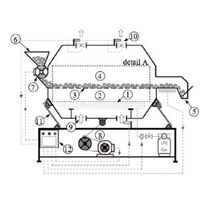

After the harvest, the paddy would contain high and unequal initial moisture content, depending on the season and harvest time. As a result, the dehydration was caused by using the dryer while feeding the paddy grain unequal moisture content, the dryer should be properly adjusted to retain the final moisture content as per the rice mill and storage requirements and low specific energy consumption (SEC) were used for the drying operation per one cycle product. The objective of this paper was to study the paddy drying operation by using a continuous cross-flow dryer at a different initial grain moisture content. The research was divided into two steps, the first step began with the drying operation with levels of the initial moisture content 20.0%wb that involved the adjustment of the parameters of an average hot-air temperature 150°C, the speed rotation of an eccentric set of 11.52 rad s–1, the airflow rate 0.016 m3 s–1, and speed rotation of rotary valve 0.21 rad s–1 (approximately feed rate 36 kg h–1), by the application of these parameters, from the obtained results, it was found that grain moisture content of paddy was reduced from 20.0%wb to 14.3%wb as desired, and SEC of 3.60 MJ kg–1 water was evaporated. Then the second step, these parameters were tested in terms of the drying operation that the initial grain moisture content decreased and increased 18.1%wb and 23.0%wb, respectively. The results showed that when the initial grain moisture content decreased, the paddy drying operation reduced the moisture of the paddy until the final grain moisture content became 12.9%wb which was lower than the desired expectation, On the contrary, when the initial moisture content increased, the final grain moisture content became 16.1%wb. This was not sufficient for storage or planting in the next crop year which required re-drying operation as well. Furthermore, the results can be used as reference data and a guideline for small communities in Thailand to appropriate decisions with the drying cost and the value-added tax.