Simple and efficient approach for shelf-life test on frozen spinach and parsley

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Accepted: 28 July 2021

Authors

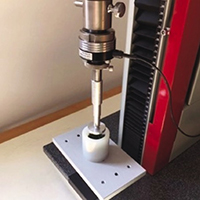

A simple test for shelf-life assessment of frozen spinach and parsley is presented. A specific shelf-life test that considers three storage temperatures is proposed to accelerate the rate of quality decay in frozen spinach and parsley. The scope was to provide a reliable and rapid way (one month vs years) to predict shelf-life by using a simple experimental approach and mathematical models based on some physical quality product attributes. Physical properties were evaluated at three storage temperatures: –5°C, –10°C and –26°C, to simulate a possible thermal abuse. Mechanical and thermal indexes were defined measuring maximum compression force (N) and latent heat involved in ice melting (J/g). A zeroorder kinetic model was used to properly fit experimental data and thus to obtain related reaction rates. The determination coefficient indicates that there is a strong linear relation between kinetic parameters at –10°C or –5°C and –26°C. This suggests a reliable procedure for shelf-life estimation, carrying out a test at –10°C or –5°C for one month and extending values to data acquired at – 26°C for the same period of time. The relations obtained from this research have led to a simple practical approach: one day at –10°C could be considered roughly equivalent to 30 days at –26°C. Accordingly, it could be possible to obtain a shelf-life estimation in short time, also considering other similar products.

Downloads

Citations

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.